About Digitally Printed Glass

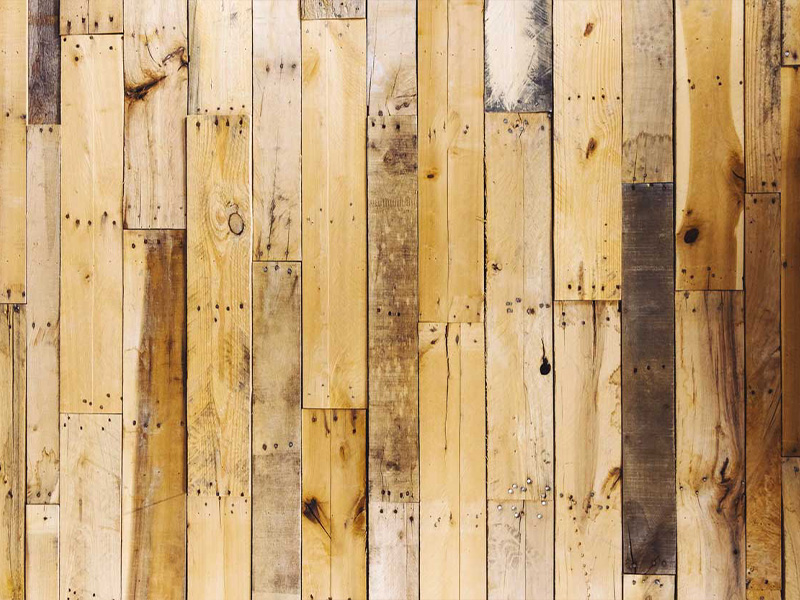

We print utilizing UV inks, the most reliable and consistent ink available. Ultra violet curing is a green technology that uses a photomechanical process to instantly dry ink after printing. This means that you can print on virtually any type of non absorbing material including glass, wood, metal, vinyl materials, and more. With UV curable ink, the ink isn’t absorbed by the material so there’s no smudging and no need for additional costly coatings.

Another great thing about UV cured inks is that they are weather-resistant and are not prone to fading. There are no solvents, no evaporation and it’s a low temperature process. Basically, the exposure to UV energy triggers a chemical reaction and causes the ink to instantly harden and is a much better alternative to solvent-based ink products

Our process starts with the glass being cut, polished, and cleaned. Next, a primer is applied to ensure the inks adhere properly. It is then cleaned again before heading to the printer. The specialized digital glass printer prints the image onto the glass surface using UV inks. At the same time the ink is applied a coat of varnish is applied to aid in scratch resistance. The ink is dried with an inline UV light to complete the process.

The final product is now ready to be shipped, installed and enjoyed.

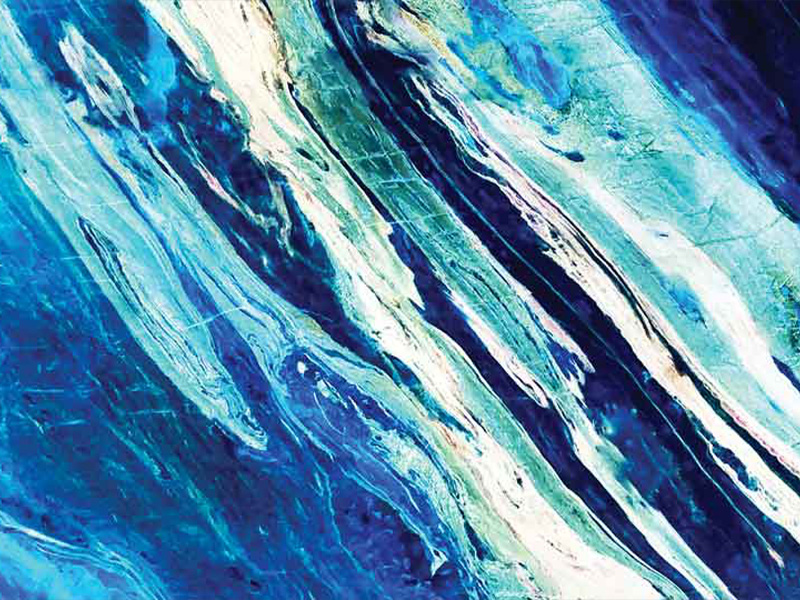

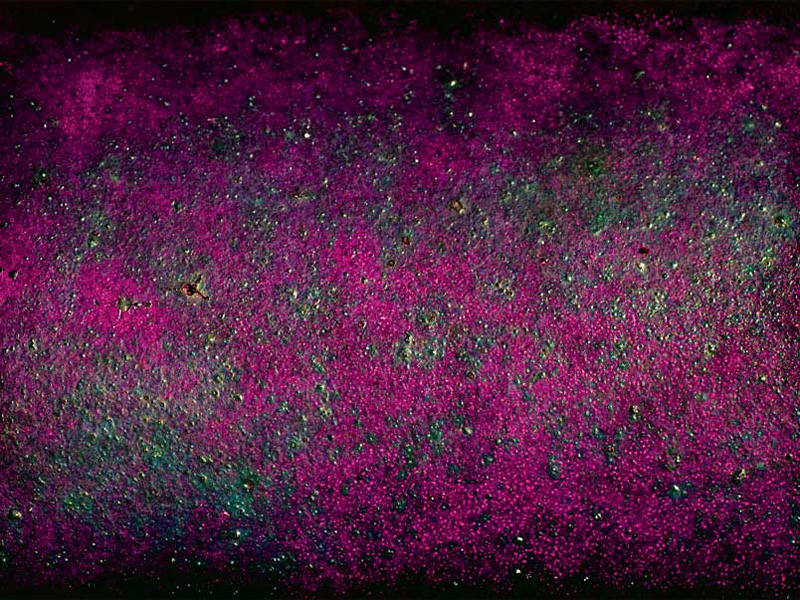

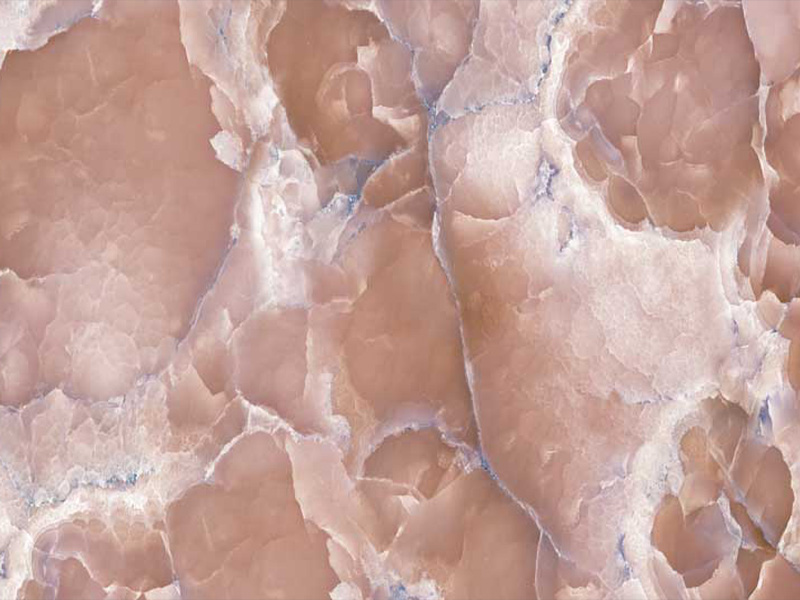

Deco Glass Collections